The non-contact ultrasonic flow meter is a non-invasive flow meter available in two formats: transit time and doppler. Both technologies feature clamp on designs with transducer arrangements that can detect in-situ flow rates from outside the pipework, without any interruption to flow or process. RS Hydro offer an extensive range of ultrasonic flow meters for sale and rental. The use of non-invasive, ultrasonic flow measurement offers great benefits in many applications. By using ultrasonic transducers clamped to the outside of pipework, there is no downtime or disruption. RS Hydro offer installation, maintenance, calibration & rental of ultrasonic flowmeters.

Transit time flow meters, or also known as 'time of flight' flow meters are mainly consigned to the measurement of clean liquids, although many flow measurement devices have a maximum tolerance of 5% solids. The principle behind this type of non-intrusive clamp-on (strap on) flow meter is that acoustic waves with a frequency of >20kHz are emitted from one transducer to the other side of the pipe back to the opposite transducer requires less time than when travelling in the opposite direction. The differential transit time of the synchronised signals is proportional to the flow rate of the fluid. Doppler flow meters using acoustic attenuation caused by the reflection of ultrasound signals from particles or gas bubbles within the liquid. Doppler ultrasonic flow meters are regarded as an old technology offering much poorer accuracies than transit time flow meters.

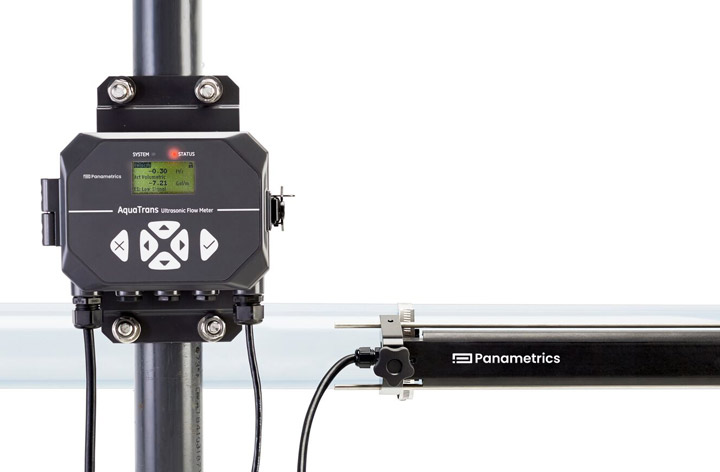

Panametrics Portable PT900 Ultrasonic Flow Meter

The Panametrics PT900 is the latest generation of portable ultrasonic clamp on flowmeter from Panametrics, it is designed to withstand rugged use in industrial applications. With superior diagnostics, functionality and accuracy this flow meter is regarded as leading edge technology. The PT900 utilises a wide selection of transducers which makes it suitable for most

applications, including many fluids, such as potable water,

wastewater, cooling and heating water, ultrapure

water and other liquids such as

water/glycol solutions, crude oil, refined

hydrocarbons, chemicals and beverages. It is suitable for most pipe sizes and materials, both

lined and unlined. We would recommend this flow meter to professionals who want the most from a portable ultrasonic flow meter. This meter has two external inputs which makes it ideal for a heat metering survey. The PT878 portable ultrasonic flowmeter was made obsolete by Panametrics in 2018, but it still available for Rental from RS Hydro.

Advantages of Clamp-On Flowmeters

- Non-invasive flow monitoring

- Measurement of non-conductive fluids

- Easily installed clamp-on sensors with no interruption to flow

- Wide range of pipe materials and sizes: 12.7-7600mm

- Process temperatures from -40°C to 200°C

- Integrated wall thickness measurement

Comparison of Ultrasonic vs Other Types of Meter

|

Meter Type

|

Advantages

|

|

Coriolis

|

Able to measure flow in medium and large pipe sizes |

|

Vortex

|

less intrusive

low flow capability |

|

Magnetic

|

can measure gas, steam & non-conductive liquids |

|

DP

|

less intrusive little or no pressure drop less need for recalibration |

|

Turbine

|

less intrusive; not subject to wear - no moving parts |

Applications for Ultrasonic Flow Monitoring

Ultrasonic flow meters can measure almost all light homogeneous fluids including water, wastewater (<5% solids) and hydrocarbons. The basic requirement is that the fluid can conduct ultrasound and have an acceptable axis-symmetrical flow. Click here to see the many fluids that ultrasonic devices can measure.

Typical applications include:

- Water distribution flow metering

- Leak Detection

- Wastewater flow-metering

- Building Services

- Inspection of fixed installation meters

- Power/Energy Management

- Chemical / Pharmaceutical

- Petro-Chemical

- Pump inspection

- Food/Hygienic flow-monitoring

- Steel

- Light Industrial

- Survey work

Ultrasonic Flowmeter Specifications

Although specifications are different between the various manufacturers, the following is intended as a guideline to ultrasonic flow meter performance and specification.

|

Flow Range

|

0.01-20m/sec (Bi-Directional) |

|

Accuracy

|

±0.5-3% of reading |

|

Repeatability

|

Typically ±0.5% |

|

Pipe Size

|

12.7-7600mm |

|

Operating Temperature

|

|

|

Transducers

|

-40°C to +200°C |

|

Transmitter

|

-10°C to 50°C |

|

Datalogging

|

Typically>100,000 data points, time stamped |

|

Output

|

4-20mA, pulse |

|

Power

|

Built-in battery with external 12v input, 8-36 hours operation |

|

Dimensions

|

Typically 250 x 150 x 40mm |

|

Weight (Control Unit)

|

Typically 3-5lbs (1-2kg) |

Ultrasonic Flow Meters : General Flow Meter Installation Requirements

For optimum accuracy the following conditions must apply:

| |

Requirement

|

|

Location

|

>10 diameters of straight-length pipework should exist upstream of the measurement point, & 5D downstream. Ideally these distances should be longer. |

|

Wall Thickness

|

For optimum accuracy, the pipe wall thickness should also be measured. Some meters are supplied with ultrasonic wall thickness gauge |

|

Liquid Medium

|

It is essential that the type of fluid is known. Also that there are no air bubbles and that the solid content does not exceed 5%. |

|

Pipe Condition

|

The pipe wall exterior should be free from dirt, paint or corrosion. For optimum accuracy the interior wall should also be free from deposits or corrosion. |