Listed on this page are those links to the detail pages for ultrasonic flow meters, electromagnetic flow meters, Vortex flow meters, insertion flow meters, coriolis flow meters and turbine flow meters, each of which have advantages and disadvantages depending on the exact detail of usage.

There is more data on the page below and still more on the detail pages for each group of flow meters.

If you need any assistance in the selection of your flow meter, please do not hesitate to call us on 01527 882060 and one of our tech support personnel will discuss your needs with you.

Ultrasonic Flow Meters

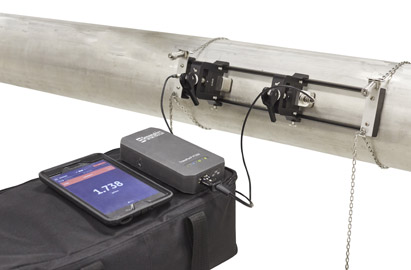

Non-invasive, ultrasonic flow meters offer great benefits in many applications. By using ultrasonic transducers clamped to the outside of pipework, there is no disruption of flow or service downtime. Ultrasonic flowmeters use transit time technology (also known as 'time of flight'). The principle behind this method of flow measurement is that acoustic waves with a frequency of more than 20 kHz are emitted from one of the transducers to the other side of the pipe and back to the second transducer and the time taken for the signal to travel is stored. This process is then reversed with a signal being sent from the second transducer being received by the first. The differential transit time of the synchronised signals is proportional to the flow rate of fluid through the pipe.

This type of flow meter is usually used for clean liquids, but we can supply flow meters that can be used on fluids with up to 5% solids. RS Hydro supply portable ultrasonic flow meters which can be used at multiple sites, permanent ultrasonic flowmeters which are designed to be used at a fixed location and hazardous area ultrasonic flow meters which are intrinsically safe for use in environments where equipment needs to be explosion proof.

Electromagnetic Flow Meters

Viscosity, pressure, temperature and density have no effect on measurement with this type of meter. Electromagnetic flowmeters can be used to measure almost all electrically conducting liquids, slurries, pastes, lyes, juices, acids and emulsions. They provide excellent accuracy and long term stability and can measure flow rate of fluids that have a conductivity as low as 0.5µS/cm (0.5µmhos).

Insertion Flow Meters

Temporary or permanently installed Insertion flowmeters can provide a flow monitoring solution that is more economical that using a full bore meter (particularly in large diameter pipes). They are also useful as a portable survey tool where occasional measurement is needed at many points. Insertion and removal can be carried out without supply disruption, by fitting gate valves at tapping points.

Turbine Flow Meters

RS Hydro supply a wide range of both full bore turbine flow meters, single jet flow meters and multi jet water flow meters. Full bore turbine flow meters use an impeller which is made of self-cleaning synthetic resin and rotates on stainless spindles mounted in the measuring chamber. For small pipe sizes (typically 5/8" to 2" diameter) mult-jet water meters are extremely accurate. These contain an impeller that is rotated by jets of water from multiple inlet ports

Heat Meters

Heat meters can be used on pipes of any size and material and are used widely in the building and industrial sectors for energy efficiency monitoring and the monitoring of hot water systems. Ultrasonic heat meters provide an easy to use, reliable and accurate method of quantifying heat energy consumption. All of the heat meters that RS Hydro supply are clamp-on, non-invasive meters and are therefore not prone to the deterioration that can occur with intrusive flow meters.