CEMEX Small Dole- Automation of Leachate Extraction System

Abstract

The installation of an automated and remotely controlled leachate well monitoring system on a landfill site in East Sussex. The brief is to allow preferential pumping and optimisation of leachate treatment plant. The installed equipment utilises solar power and telemetry to monitor leachate levels and control compressed air driven pumps.

Equipment Used

An Adcon Remote Telemetry Unit (RTU) designed to control 4 solenoid values is deployed at each well. The RTU also has 4 pulse inputs for flow meters and one analogue input which is utilised with a Keller ATEX approved Level sensor and Zener barrier installed. One RA440 GPRS to local radio telemetry is installed on site for remote operation and data collection. Adcon addVANTAGE Pro software has been configured to control pumps and record and display the data via the internet. Flowing alongside the site is a tidal river which also required a level monitoring station linked into the well monitoring.

Background

In 2005 CEMEX inherited Small Dole landfill site in East Sussex when it acquired RMC. This is a shallow landfill site in an old clay pit bordered by the tidal River Adur. The poor clay cap means that rainfall quickly percolates into landfill. The closeness of the river also causes concern as there may be a hydrologic link. The tightening up of the Environment Agency Licence on discharges meant upgrading and refurbishing the existing leachate treatment plant. As part of this work a new system to manage the leachate in the cells was installed, to ensure compliance is not only met but exceeded. Eleven additional wells were drilled alongside the river bringing a total of 32 wells on site. Because of the methane and associated risks there is no power provision at the wells other than a compressed air supply ring main which runs around the site feeding the air pumps in the wells. Another ring main transfers the leachate to the treatment plant. The monitoring needed to include the pumps performance in terms of operation and discharge. Consideration was given to air volumes being used and volumes of untreated leachate being pumped to the treatment plant.

In 2005 CEMEX inherited Small Dole landfill site in East Sussex when it acquired RMC. This is a shallow landfill site in an old clay pit bordered by the tidal River Adur. The poor clay cap means that rainfall quickly percolates into landfill. The closeness of the river also causes concern as there may be a hydrologic link. The tightening up of the Environment Agency Licence on discharges meant upgrading and refurbishing the existing leachate treatment plant. As part of this work a new system to manage the leachate in the cells was installed, to ensure compliance is not only met but exceeded. Eleven additional wells were drilled alongside the river bringing a total of 32 wells on site. Because of the methane and associated risks there is no power provision at the wells other than a compressed air supply ring main which runs around the site feeding the air pumps in the wells. Another ring main transfers the leachate to the treatment plant. The monitoring needed to include the pumps performance in terms of operation and discharge. Consideration was given to air volumes being used and volumes of untreated leachate being pumped to the treatment plant.

Project Monitoring Approach

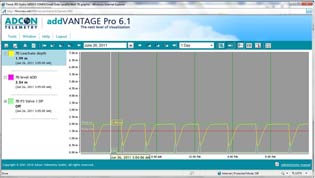

Three pumps were initially installed in each well, each one needing individual control and monitoring. One Adcon Telemetry addSWITCH remote telemetry unit(RTU) has the ability to control 4 solenoid valves, 4 pulse inputs and 1 analogue input for the level sensor. Pulse counters on the air supply to the pump were fitted with reed switches to count the number of strokes of each pump. This monitored the performance and correct operation of each pump with an approximation of how much leachate was being pumped. A requirement for an increase in pumping capacity meant in each of the new wells a single diaphragm pump replaced the displacement air pumps which are still controlled by the operation of a solenoid valve. The new pumps cannot be monitored using the pulse counters so small flow meters are being tested on each discharge line. Each well has an ATEX approved level sensor 0.5m from the bottom of the well with a Zener barrier to protect against sparks and current surges. The level sensor reading, pump status and counter responses are stored as 5-minute data slots. The Adcon RTUs on site are requested in turn via a GPRS link to the RA440. The RA440 then uses lower powered telemetry to request the stored data from each addSWITCH. The Adcon software processes this data to give an actual level and a level to Above Ordinance Datum (AOD). The importance of the AOD reading is so each well can be compared to the other wells on site and with the river level. On the level control side of the application the leachate depth in the well is compared to the configured well pump start/stop thresholds. The appropriate command is transmitted back to site and onto the addSWITCH at the relevant well. The solenoid valve is actuated and a confirmation is transmitted back to the software. Manual on/off commands as well as a run time duration can be sent to each individual valve. Trigger thresholds can be adjusted via the web based software.

Three pumps were initially installed in each well, each one needing individual control and monitoring. One Adcon Telemetry addSWITCH remote telemetry unit(RTU) has the ability to control 4 solenoid valves, 4 pulse inputs and 1 analogue input for the level sensor. Pulse counters on the air supply to the pump were fitted with reed switches to count the number of strokes of each pump. This monitored the performance and correct operation of each pump with an approximation of how much leachate was being pumped. A requirement for an increase in pumping capacity meant in each of the new wells a single diaphragm pump replaced the displacement air pumps which are still controlled by the operation of a solenoid valve. The new pumps cannot be monitored using the pulse counters so small flow meters are being tested on each discharge line. Each well has an ATEX approved level sensor 0.5m from the bottom of the well with a Zener barrier to protect against sparks and current surges. The level sensor reading, pump status and counter responses are stored as 5-minute data slots. The Adcon RTUs on site are requested in turn via a GPRS link to the RA440. The RA440 then uses lower powered telemetry to request the stored data from each addSWITCH. The Adcon software processes this data to give an actual level and a level to Above Ordinance Datum (AOD). The importance of the AOD reading is so each well can be compared to the other wells on site and with the river level. On the level control side of the application the leachate depth in the well is compared to the configured well pump start/stop thresholds. The appropriate command is transmitted back to site and onto the addSWITCH at the relevant well. The solenoid valve is actuated and a confirmation is transmitted back to the software. Manual on/off commands as well as a run time duration can be sent to each individual valve. Trigger thresholds can be adjusted via the web based software.

For compliance reasons manual dipping still takes place every Friday.

The design and installation of the Adcon equipment is to allow the site to become fully automated using remote monitoring and control to allow preferential pumping of wells nearing the compliance level when the treatment plant is near capacity. Any site visits would be to deal with any problems as they occur.

Results

All the data produced by the addSWITCHes on site and the control of the pumps is available to CEMEX via the internet on the web based software.

The pumps are switched on and off based on the level sensor; the level can be adjusted in the software without visiting the site. There is an option to run the pumps on a timed duration when the trigger threshold is reached if this is required.

The pumps are switched on and off based on the level sensor; the level can be adjusted in the software without visiting the site. There is an option to run the pumps on a timed duration when the trigger threshold is reached if this is required.

More than one valve may be used to control a pump giving 2 pump speeds by increasing air supply.

There is a significant reduction in time spent on site checking the pumps with any time on site directed to the areas needing attention.

Pump flow meters indicate which pumps are operating and the flow rate. The Adcon software indicates whether the air supply valve is open or closed.