- Versatile Can be used for a wide range of pipe sizes, materials and fluids

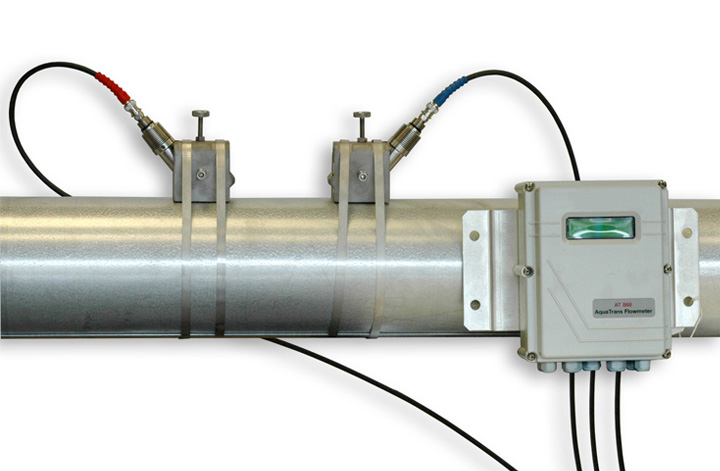

- Clamp-on Flow Measurement Convenient, non-intrusive measurement with no need to cut into the pipe

- Quick & Easy Installation Simple programming and four step transducer installation

- MCERTS Certification

Case Studies

Overview

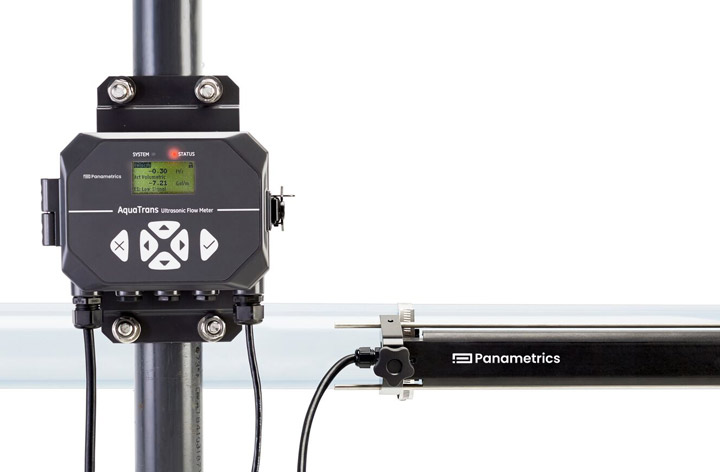

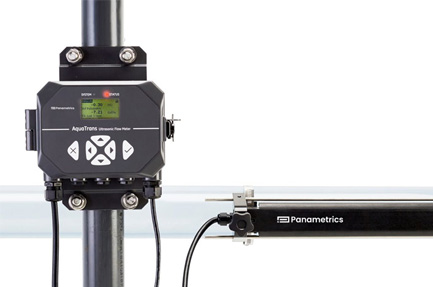

The AquaTrans AT600 clamp-on ultrasonic transmitter provides flow measurement in a low-cost package which can be installed at the measurement point. It has been designed specifically for use in full bore pipes in water and wastewater applications but is not limited to use in just these applications. The AT600 benefits from no moving parts, therefore, minimal maintenance is required. Patented Correlation Transit-Time™ technology is used to achieve long-term, drift free operation.

Clamp-on transducers offer maximum convenience, flexibility and a low installation cost compared to traditional flow metering technologies.

Manufactured by: Panametrics

Model: AT600 Clamp On Liquid Flow Meter

Services offered for this product

- Sales

- Rental

- Installation

- Calibration

- Maintenance

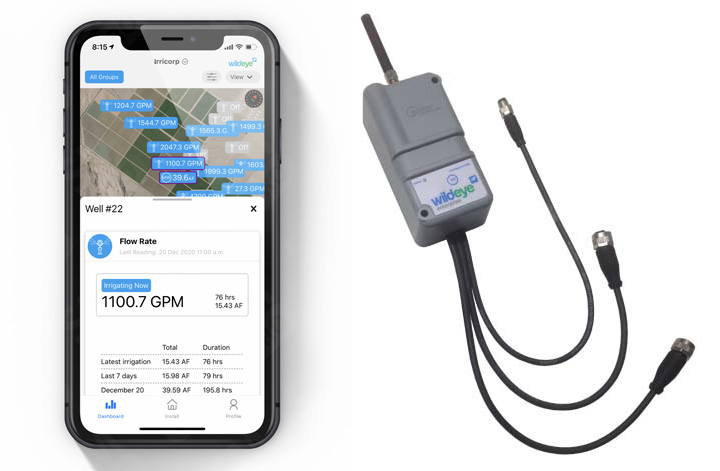

- IoT Cloud Compatible

Applications

Potable water

Sewage

Wastewater

Treated water

Discharge water

Cooling and heating water

Irrigation water

Other industrial fluids

Specification

| Fluid Types | Liquids: acoustically conductive fluids, including most clean liquids, and many liquids with small amounts of entrained solids or gas bubbles |

| Flow Measurement | Patented Correlation Transit-TimeTM mode |

| Pipe Sizes | 15 mm to 7600 mm (1/2 inch to 300 inch) |

| Pipe Materials | All metals and most plastics. Consult RS Hydro for concrete, composite materials, and highly corroded or lined pipes. |

| Accuracy | ±1% of reading in application, ≥2 in. (50 mm) pipe and >1 ft/s (0.3 m/s) velocity ±2% of reading in application, <2 in. (50 mm) pipe and >1 ft/s (0.3 m/s) velocity ±0.5% in field calibration Installation assumes a fully developed, symmetrical flow profile (typically 10 diameters upstream and 5 diameters downstream of straight pipe run). Final installation accuracy is a function of multiple factors including fluid, temperature range, pipe centricity and others. |

| Calibration | All meters are water calibrated and delivered with a traceable calibration certificate. |

| Repeatability | ±0.2% of reading |

| Range (Bidirectional) | -40 to 40 ft/s (-12.19 to 12.19 m/s) |

| Rangability (Overall) | 400:1 |

| Measurement Parameters | Velocity, Volumetric, and Totalized Flow |

| Electronics | |

| Enclosure | Epoxy-coated aluminum weatherproof Type 4X/IP67 |

| Dimensions | 6.6 x 5.0 x 2.4in (168 x 128 x 61mm) Weight: 3.5 lbs/1.5kg |

| Channels | One channel |

| Display | Graphic LCD (128 x 64 pixels) |

| Keypad | Six-button keypad, for full functionality operation |

| Error Display Indicator | Green or red light |

| Power Supplies | Standard: 85 to 265 VAC, 50/60 Hz Optional: 12 to 28 VDC, ± 5% |

| Power Consumption | 10 Watts in rush 5 Watts normal operation |

| Operating Temperature | -4°F to 131°F (-20°C to 55°C) |

| Storage Temperature | -40°F to 158°F (-40°C to 70°C) |

| Outputs (Based on Configuration) |

Note: Analog outputs are Namur NE43 compliant |

| Certification | CE, UL, CSA, (MCert approval pending) |

| Clamp-On Ultrasonic Flow Transducers | |

| Temperature Ranges | Standard: -40°F to 302°F (-40°C to 150°C) See specific transducer for exact temperature range. |

| Mounting Fixture | Anodized aluminum with stainless steel strapping |

| Couplant | Standard: Solid couplant Optional: Liquid couplant |

| Rating | Standard: General purpose (IP66 or IP68) Note: See specific transducer model for exact rating. |